Understanding Progressive Die Technology

What is a Progressive Die?

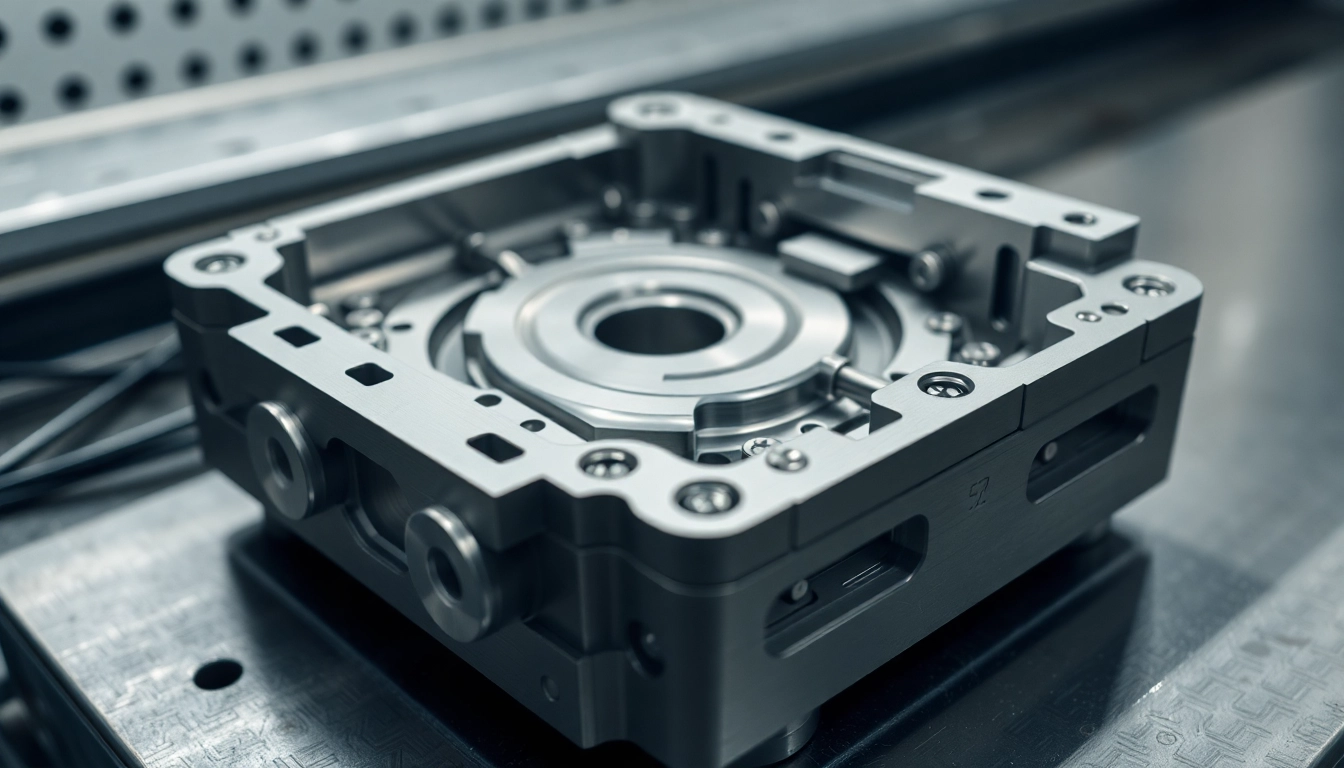

Progressive dies play a crucial role in the manufacturing of metal components. A progressive die is a specialized tool used in metal stamping processes, designed to cut, shape, and form parts through multiple operations that occur in a single pass through the die. This innovative tool enables the production of complex shapes with high precision and efficiency, significantly reducing manufacturing time and increasing output.

The progressive die consists of various stations that perform a sequence of operations—from blanking and forming to bending and punching—allowing manufacturers to produce intricate designs that meet tight tolerances. With the ability to handle complex geometries, progressive dies are essential in industries such as automotive, electronics, and appliance manufacturing. They embody a blend of engineering skill and cutting-edge technology, exemplifying the capabilities of modern precision craftsmanship. For more detailed information about the technology and its applications, visit our page on Progressive Die manufacturing.

Components of Progressive Dies

A progressive die comprises several integral components that work together to achieve precise and efficient metal forming. These components include:

1. Die Plates: These are the foundational elements where all operations take place. Typically made of high-quality steel, die plates provide stability and strength during the stamping process.

2. Punches and Strippers: Punches are used to cut or form material through the die, while strippers help remove the formed parts from the die, ensuring a smooth transition between operations.

3. Guide Pins and Bushings: These components ensure that the alignment of the die is precise, maintaining the accuracy of the part being produced through consistent positioning.

4. Ejector Pins: After the stamping operation is completed, ejector pins assist in removing the finished component from the die, preventing damage and facilitating a continuous production flow.

5. Cutting Edges: These are sharp edges designed for cutting the material during the blanking operation. Their geometry and sharpness significantly influence the quality and accuracy of the final product.

Understanding each component’s role within a progressive die allows manufacturers to tailor their die designs to specific production requirements, enhancing efficiency and reducing scrap material.

Applications in Metal Stamping

Progressive dies are widely used across various industries due to their efficiency and precision in metal stamping operations. Key applications include:

– Automotive Industry: Progressive dies are crucial for producing parts such as brackets, clips, and component housings, streamlining the production of essential parts that ensure vehicle safety and functionality.

– Electronics: In electronics manufacturing, precision stamped components like connectors and housings depend on progressive dies for high-volume production with minimal tolerances.

– Appliance Manufacturing: From metal frames to internal components, appliances heavily rely on progressive die technology to produce durable and reliable parts.

– Medical Devices: With stringent regulatory standards, the medical field benefits from the precision of progressive dies for producing components that require high accuracy and reliability.

The versatility of progressive dies makes them indispensable for efficiently producing a vast array of products without sacrificing quality.

The Precision Machining Process

CNC Machining vs. Precision Machining

Understanding the difference between CNC machining and precision machining is crucial for manufacturers looking to enhance their production capabilities. CNC (Computer Numerical Control) machining uses computerized controls to automate the movement of machines, providing high levels of accuracy and repeatability for various machining processes.

In contrast, precision machining refers to a broader category that encompasses various manual and automated techniques that produce parts to extremely tight tolerances. While CNC machining is a subset of precision machining, not all precision machining involves CNC processes. Techniques like jig grinding, wire EDM, and conventional milling or turning also fall under the umbrella of precision machining.

The key takeaway is that while CNC machining provides automation and efficiency, precision machining emphasizes delivering parts with tight tolerances and high-quality finishes, regardless of the method employed.

Choosing Materials for Progressive Dies

Material selection is a pivotal factor in designing and manufacturing progressive dies. The right material ensures durability, performance, and the ability to withstand the stresses and impacts during stamping operations. Typically, materials such as:

– Hardened Tool Steel: Known for its strength and wear resistance, hardened tool steel is a popular choice for die components that require longevity and performance stability.

– Stainless Steel: Corrosion-resistant steel is often used in progressive dies, especially for applications exposed to harsh environments.

– Aluminum Alloys: These materials offer a lightweight alternative while maintaining adequate strength, making them suitable for specific applications where weight savings are essential.

– Engineering Plastics: In some cases, plastics may be used for specific components to reduce weight and cost, particularly in industries where non-metal components are acceptable.

Choosing the right combination of materials is critical to optimizing die life and ensuring consistent production quality.

Steps in Die Fabrication

The die fabrication process involves several crucial steps, each contributing to the precision and efficiency of the final product. Here’s a breakdown of the typical stages in die fabrication:

1. Design: Initial design involves CAD (Computer-Aided Design) modeling to create a detailed plan of the die, accounting for all necessary operations and tolerances.

2. Material Selection: Selecting the appropriate materials based on the application and functional requirements.

3. Machining: Using CNC machines and other precision machining processes to craft the various components of the die accurately.

4. Assembly: Integrating all parts of the die, ensuring alignment and fit before proceeding to testing.

5. Testing and Validation: Carrying out tryout tests to assess the performance of the die, making adjustments as necessary to achieve desired outcomes.

6. Finalization: After successful testing, the die is finalized and prepared for production, ensuring that all specifications are met and quality standards are upheld.

This structured approach to die fabrication allows manufacturers to meet the complex demands of modern production while maintaining quality and efficiency.

Quality Assurance in Die Manufacturing

Importance of Inspections and Testing

Quality assurance is a fundamental aspect of die manufacturing that ensures components meet specific standards and specifications. Implementing rigorous inspection and testing protocols allows manufacturers to identify potential issues early in the process, reducing scrap rates and enhancing production efficiency.

Key inspection techniques include:

– CMM (Coordinate Measuring Machine) Inspections: These machines provide precise measurements of the die components, analyzing their geometrical characteristics against set parameters.

– Visual Inspections: Simple yet effective visual checks to identify defects or irregularities in the die components that could affect performance.

– Functional Testing: Evaluating the die during trial runs identifies any adjustments needed before full-scale production begins.

By prioritizing quality assurance, manufacturers can ensure their progressive dies perform optimally and deliver consistent results.

Implementing ISO 9001:2015 Standards

Compliance with ISO 9001:2015 standards represents a commitment to quality management and continuous improvement in die manufacturing. This internationally recognized standard outlines the criteria for a quality management system that enhances customer satisfaction and operational efficiency.

Key components of ISO 9001:2015 include:

– Customer Focus: Prioritizing customer needs to ensure products meet specified requirements.

– Leadership: Establishing a strong leadership framework to influence organizational culture and promote accountability.

– Engagement of People: Involving all employees in the quality management process enhances productivity and innovation.

– Process Approach: Understanding and managing interrelated processes to ensure efficient operations and desired outcomes.

– Continuous Improvement: Cultivating an environment that fosters ongoing improvements, enabling manufacturers to adapt to changing market demands and enhance product quality.

By implementing ISO 9001:2015 standards, companies signal their commitment to quality and reliability, instilling confidence in their clients.

Continuous Improvement Strategies

Continuous improvement is a vital strategy in modern manufacturing that allows companies to enhance processes, products, and services iteratively. Implementing methodologies like Lean Manufacturing and Six Sigma can lead to significant improvements in efficiency and waste reduction.

– Lean Manufacturing: By identifying and eliminating non-value-added activities, Lean principles foster a streamlined production process that enhances efficiency and responsiveness.

– Six Sigma: Focused on reducing defects and variances in processes, Six Sigma uses data-driven approaches to improve quality and performance.

– Employee Training and Development: Investing in workforce training promotes skill development, empowering employees to contribute to quality improvement actively.

– Feedback Mechanisms: Establishing robust feedback loops allows companies to capture insights from customers and employees, facilitating adjustments based on firsthand experiences and observations.

Through these continuous improvement strategies, manufacturers can maintain competitive advantages and adapt to evolving industry standards and customer expectations.

Innovations and Technologies in Die Design

Advancements in CNC Milling

CNC milling technology has seen significant advancements, enhancing precision and efficiency in die manufacturing. Modern CNC mills incorporate sophisticated software and control systems that provide operators with unparalleled flexibility and capability. Key innovations include:

– 5-Axis Machining: This technology allows for complex geometries to be machined in a single setup, significantly reducing production time and enhancing accuracy.

– Adaptive Machining: Advanced CNC milling machines can adjust their operations based on real-time feedback, optimizing cutting paths and speeds for improved efficiency and tool life.

– Automation Integration: The integration of robotics and automated systems in CNC milling enhances production scales and reduces labor costs, allowing for night operations without human oversight.

Embracing these advancements in CNC milling leads to faster, more precise die manufacturing, essential for meeting the demands of modern production schedules.

Utilizing 3D Design in Die Manufacturing

The use of 3D design technology has revolutionized die manufacturing, allowing for highly accurate modeling and visualization before the physical fabrication begins. Key benefits include:

– Enhanced Visualization: 3D modeling enables designers and clients to visualize the final product, facilitating better communication and understanding of the design intent.

– Simulation Capabilities: Manufacturers can simulate the die’s performance under various conditions, identifying potential design flaws and rectifying them early in the process.

– Rapid Prototyping: 3D printing and rapid prototyping technologies allow for quick iterations of die designs, enabling manufacturers to test and validate concepts more efficiently.

The embrace of 3D design technology streamlines the design process, reduces lead times, and enhances product quality, making it a cornerstone of modern die manufacturing practices.

Future Trends in Precision Tooling

As technology continues to evolve, several future trends are emerging that will shape the landscape of precision tooling and die manufacturing:

– Digital Twins: The concept of creating a digital twin—a virtual model of a die—will allow for ongoing performance monitoring and predictive maintenance, reducing downtime and costs.

– Augmented Reality (AR): AR technologies will enable technicians to visualize complex die assemblies and operations in real-time, enhancing training and reducing errors.

– Sustainability Initiatives: An increasing focus on sustainable manufacturing practices will influence materials and processes, leading to innovations in eco-friendly production techniques.

– Advanced Materials: The development of new materials that offer improved properties will enhance die longevity and performance, addressing new requirements across industries.

Embracing these trends ensures manufacturers remain competitive and prepared for the future landscape of precision tooling and die manufacturing.

Our Commitment to Client Satisfaction

Collaborative Excellence in Projects

At Dongguan Chaoyang Hardware Products Co., Ltd., we believe that collaboration is key to achieving excellence. Our approach to client projects emphasizes building strong partnerships that facilitate open communication and shared goals. By engaging closely with our clients throughout the design and manufacturing process, we ensure their requirements and expectations are met, if not exceeded.

We prioritize client involvement from the initial design stage through to production, allowing for feedback integration and adaptation. This collaborative spirit fosters innovation and results in higher-quality outputs that reflect the client’s vision and specifications.

Client Testimonials and Case Studies

Our commitment to quality and precision has been recognized by various clients across industries. We take pride in our testimonials, demonstrating how we have positively impacted our partners’ success through innovative solutions and exceptional service.

Case studies highlight specific projects where our progressive dies have significantly improved our clients’ manufacturing processes. These documented successes provide tangible evidence of our capabilities and further reinforce our dedication to delivering excellence in every project.

Support and Consultation Services

In addition to our manufacturing capabilities, we offer comprehensive support and consultation services to help our clients navigate the complexities of tooling and die design. Our experienced team is available to provide insights on material selection, die design optimization, and production processes, ensuring clients receive tailored advice that aligns with their unique needs.

Whether you need assistance during the design phase or require troubleshooting during production, our support services are designed to provide the expertise and resources necessary for successful outcomes. Our focus on putting people first extends to our client support initiatives, reflecting our commitment to building long-lasting relationships that drive mutual success.