Understanding Adhesive Films

Definition and Composition

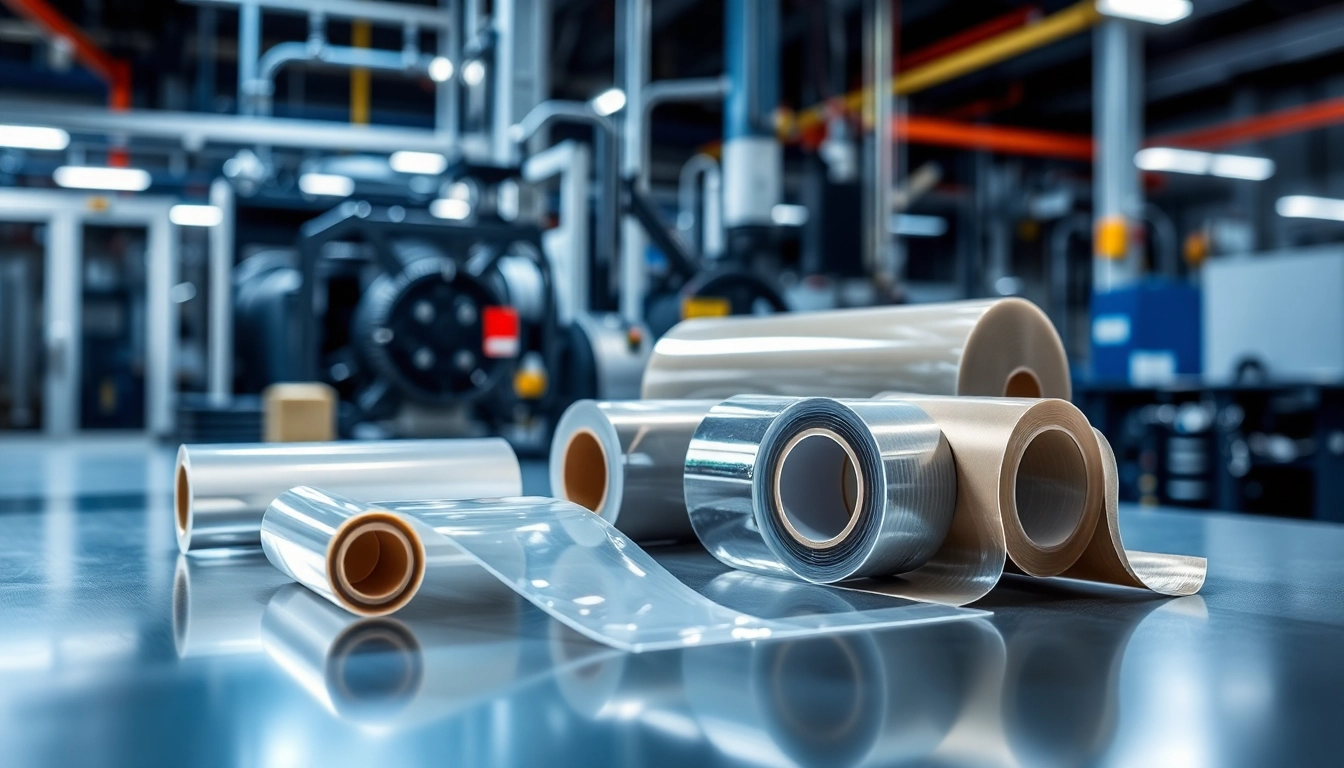

Adhesive films are a specialized form of adhesive material, typically produced in thin layers, that adhere to surfaces upon activation. These films are designed to offer consistent bonding characteristics across various applications. The composition of adhesive films generally includes polymers, sometimes blended with additives to enhance their performance attributes, such as flexibility, strength, and temperature resistance. The production process often involves precision casting or extrusion techniques to achieve uniformity in thickness and quality.

Types of Adhesive Films

There are several types of adhesive films available, each formulated to meet specific bonding requirements. Some of the common types include:

- Structural Adhesive Films: These films are engineered for high strength and durability, often used in applications that require load-bearing capabilities.

- Lightweight Damping Adhesive Films: Designed to reduce noise and vibration, these films are commonly used in automotive and aerospace applications.

- Thermal Interface Adhesive Films: These films enhance heat transfer in electronic applications, ensuring efficient cooling and thermal management.

- Pressure-Sensitive Adhesive Films: These films adhere without the need for heat or solvent activation, making them versatile and easy to apply.

Applications in Various Industries

Adhesive films are employed in a variety of industries due to their remarkable bonding capabilities. They play a critical role in:

- Aerospace: Used for bonding composite materials in aircraft assembly, contributing to weight reduction and structural integrity.

- Automotive: Essential in manufacturing components that require lightweight, durable, and flexible bonding solutions, such as body panels and interior parts.

- Defense: Utilized in military applications where high performance and reliability are crucial, including the production of armored vehicles and aircraft.

- Electronics: Used for assembling components in devices such as smartphones and tablets, where thermal management is vital.

Benefits of Using Adhesive Films

Strength and Durability

One of the primary benefits of adhesive films is their high strength and durability. These films are engineered to withstand various stresses and environmental conditions, ensuring long-lasting performance. Their ability to create strong bonds enhances the overall structural integrity of the assembled materials, making them particularly suitable for demanding applications.

Cost-Effectiveness

Adhesive films can be a cost-effective solution when compared to traditional bonding techniques such as welding or mechanical fastening. They simplify manufacturing processes, reduce labor costs, and minimize the need for additional materials. Moreover, the reduction of weight in applications like automotive and aerospace can significantly lower fuel and operating costs.

Ease of Use

Adhesive films are designed for straightforward application, which can be done through various methods such as heat or pressure activation. This ease of use leads to quicker production times and less potential for errors during assembly. Additionally, the consistent thickness and properties of adhesive films allow for predictable and repeatable bonding outcomes.

Factors to Consider When Choosing Adhesive Films

Material Compatibility

It is crucial to choose adhesive films that are compatible with the materials being bonded. Different substrates may require specific adhesive formulations to achieve optimal performance. A thorough understanding of the chemical and physical properties of both the adhesive film and the substrates can prevent issues like delamination or weak bonds.

Temperature Resistance

Temperature resistance is a significant factor when selecting adhesive films, especially in applications exposed to extreme heat or cold. Knowing the operating temperature range ensures the chosen adhesive film can maintain its properties without degradation. This is especially relevant in industries like automotive and aerospace, where environmental conditions can vary widely.

Thickness and Application Method

The thickness of the adhesive film affects its overall performance, including bond strength and flexibility. Additionally, the chosen application method—whether it be heat-activated, pressure-sensitive, or solvent-bonding—can influence which type of adhesive film is best suited for a particular task. Assessing the desired outcome and application environment will lead to informed decision-making.

Best Practices for Application of Adhesive Films

Surface Preparation Techniques

Proper surface preparation is vital for ensuring the effectiveness of adhesive films. This process includes cleaning surfaces to remove contaminants such as grease, dust, or moisture, which can interfere with bonding. Techniques like sanding, solvent cleaning, or plasma treatment can enhance adhesion. Following the manufacturer’s recommendations for surface preparation will lead to optimal results.

Application Temperature and Pressure

The specific temperature and pressure conditions during the application of adhesive films can significantly impact their performance. Adhering to recommended activation temperatures ensures the adhesive film reaches its ideal bonding properties. Similarly, applying the correct pressure aids in eliminating air pockets and ensuring full surface contact, which contributes to the bond’s effectiveness.

Post-Application Testing

After applying adhesive films, conducting post-application testing is essential to verify bond strength and durability. This can involve peel tests, shear tests, or environmental exposure tests. These evaluations provide insights into the performance of the bond and help identify any potential weaknesses before the final product is completed. Regular testing can also guide future improvements in the selection and application of adhesive films.

Future Trends in Adhesive Film Technology

Innovations in Material Properties

As industries continue to evolve, innovations in adhesive film technology are emerging. Advances in material science are leading to the development of films with enhanced properties, such as increased flexibility, greater heat resistance, and improved environmental resilience. These innovations aim to meet the rising demands for higher performance in lightweight structures and multifunctional applications.

Environmental Considerations

With growing awareness of sustainability, there is an increasing push for eco-friendly adhesive solutions. Future adhesive films may incorporate renewable materials, lower volatile organic compounds (VOCs), and be designed for easier recycling. This not only aligns with regulatory requirements but also caters to consumer preferences for sustainable products.

Industry Growth and Predictions

The adhesive film market is expected to experience significant growth in the coming years, driven by advancements in technology and increased adoption across various industries. As manufacturers seek to enhance performance while reducing costs and weight, the demand for sophisticated adhesive films will continue to rise. This growth presents opportunities for innovation and differentiation in product offerings.

In conclusion, understanding adhesive films and their applications is becoming increasingly important in various industries. By recognizing the benefits they offer, considering key factors in material selection, adhering to best practices for application, and being aware of future trends, businesses can leverage adhesive films to enhance product performance and efficiency. For more detailed specifications and product offerings, visit https://www.makobond.com/adhesives-films.